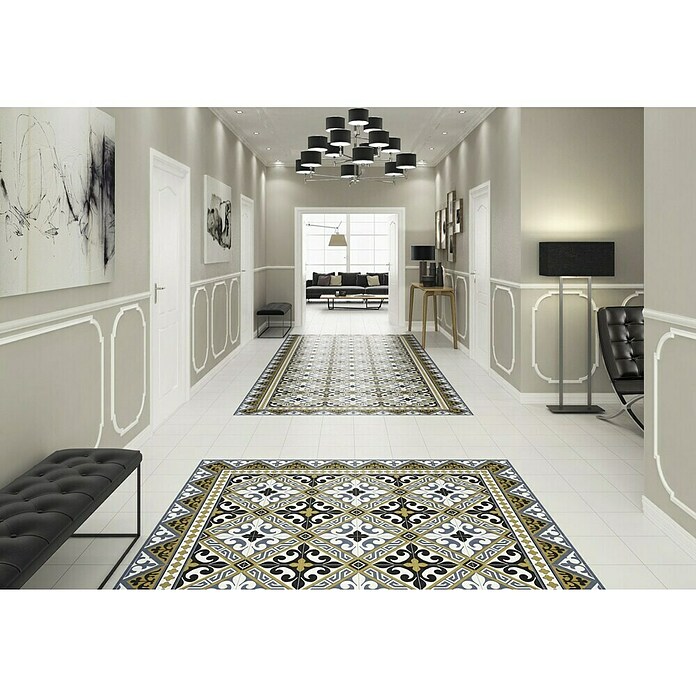

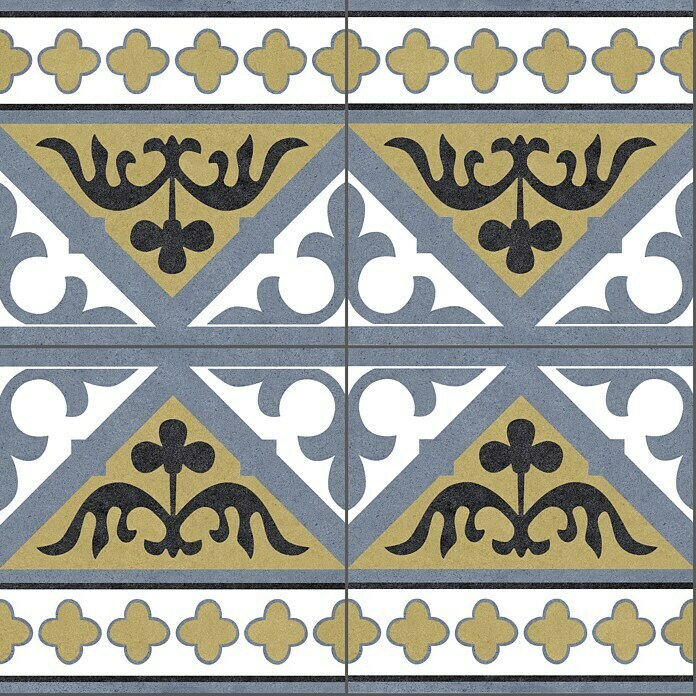

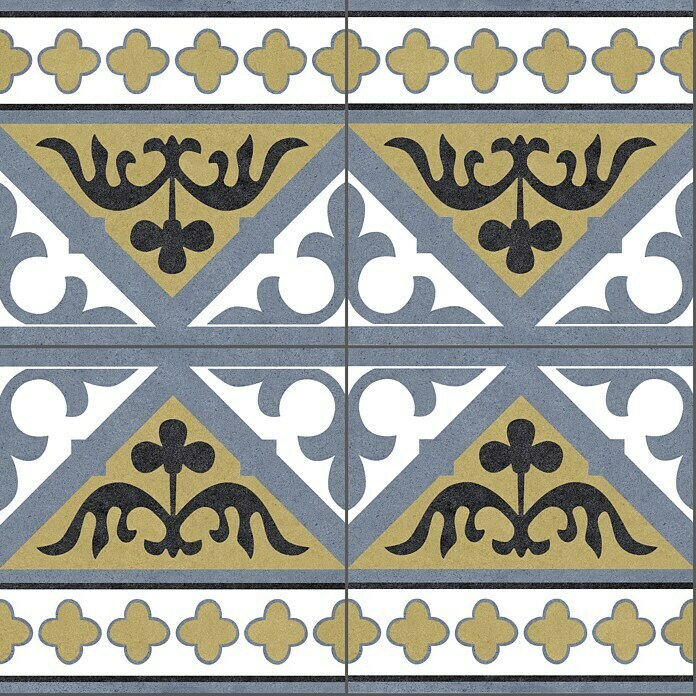

Orleans tile border

25 x 25 cm, blue/white/black/brown, matt

(145)

- Glazed tile border made of porcelain stoneware in a matt vintage look for indoor and outdoor use

- Can be laid on both the wall and the floor

- Easy care and cleaning thanks to the dirt-repellent surface

- Regular joint pattern thanks to calibrated edges

- Slip-resistant properties (R9) and suitability for areas subject to heavy use

Prod.Nr. : 26376682

$3.50

per piece incl. VAT

1

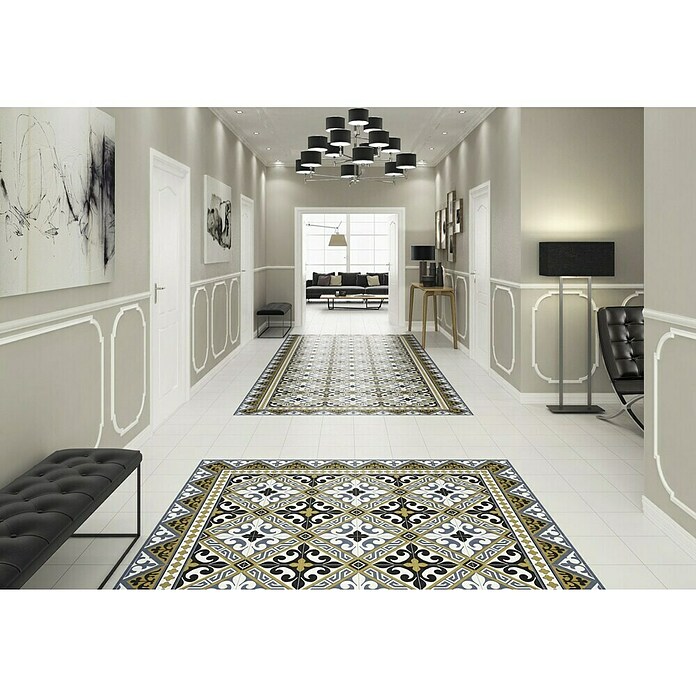

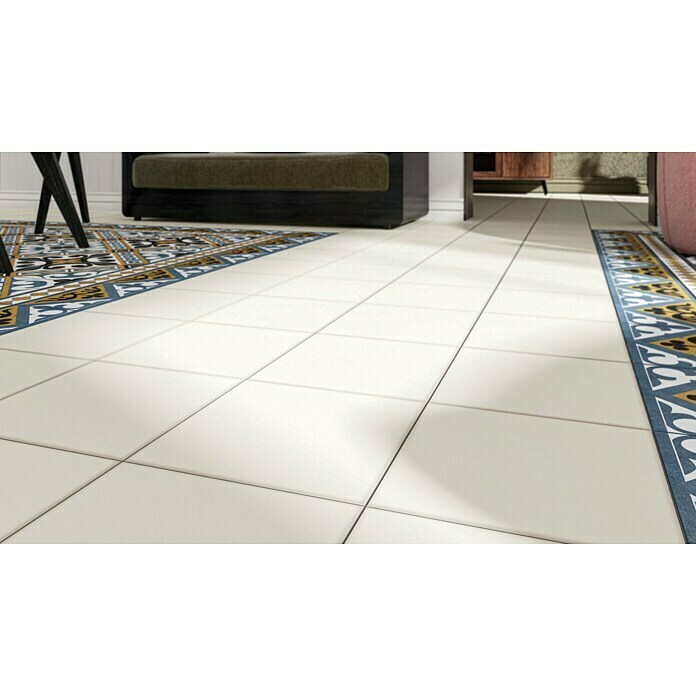

The glazed tile border, also known as the classic floor tile, is characterized by its special vintage look. It sets decorative accents and creates a homely ambience. The product therefore not only serves functionality, but also forms a unique design element.

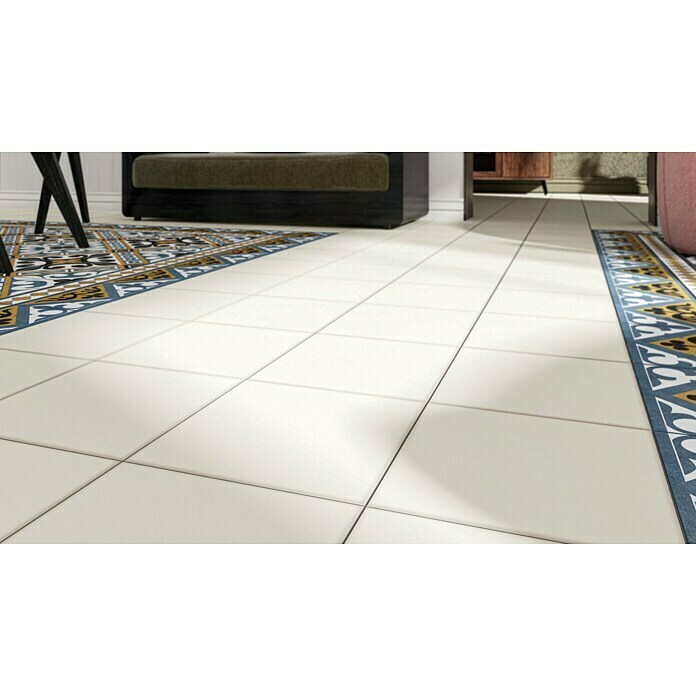

Area of application: The tile is used in the living area and in the bathroom and is usually laid on floors. But it can also be used as a wall tile. In addition, thanks to its frost protection, the tile can be used outdoors without hesitation.

Advantages of the tile border:

- Easy care: Since fine stoneware is highly resistant to acids, it can be maintained very easily. Among other things, you can use citric acid or vinegar. This can be used to easily remove rust or limescale, for example. In most cases, the tiles can be cleaned with warm water because they are dirt-repellent.

- Moisture resistance: In the production of the tile border, the materials are finely ground and then melted together. Due to their high melting point, they can be almost completely combined. The materials are then pressed under very high pressure. For these reasons, porcelain stoneware tiles can hardly absorb any liquid and are therefore almost waterproof.

- Frost resistance: Due to the low water absorption of the tile, it is frost-proof when installed professionally. This makes them ideal for laying on balconies and terraces.

- Abrasion group 4: The tile is suitable for areas subject to heavy wear. This includes floor coverings in kitchens, hallways, living rooms, offices, or terraces.

- Slip resistance: The tile border has the slip resistance group R9. This means that it only has a low coefficient of static friction. The tile is therefore slip-proof for angles of inclination of 6-10° and is suitable for stairs, dining rooms or entrance areas.

- White-body: Due to the raw materials used in production, the tile body is white. This is the back of the tiles. White-body tiles are particularly characterized by their good quality. They are also particularly suitable when using light or colored grout, as the shards are not noticeable.

- Longevity: The material makes the tile scratch-resistant and fire-resistant. It is also resistant to bacteria, viruses, fungi and mold.

Edge processing:

- Calibrated: The tile border is pressed into shape during production. This creates a slightly angled edge. The edges are then trimmed so that very uniform edges can be achieved. This means that the tiles can then be laid with regular joints and the size of the joints can be minimized.

Surface treatment:

- Glazed: By applying a glass-like compound to the surface of the tile, a slip-resistant surface is achieved. The glaze also serves as a protective layer for the tiles. This is particularly suitable for tiles on walls and floors in living areas.

Abrasion group

4 - Heavy use

Color

Blue/White/Black/Brown

Gloss level

Frosted

Edge processing tile

Calibrated

Material tile

Porcelain stoneware

Surface treatment tile

Glazed

Slip safety group according to DIN 51130

R9

Shards

White body

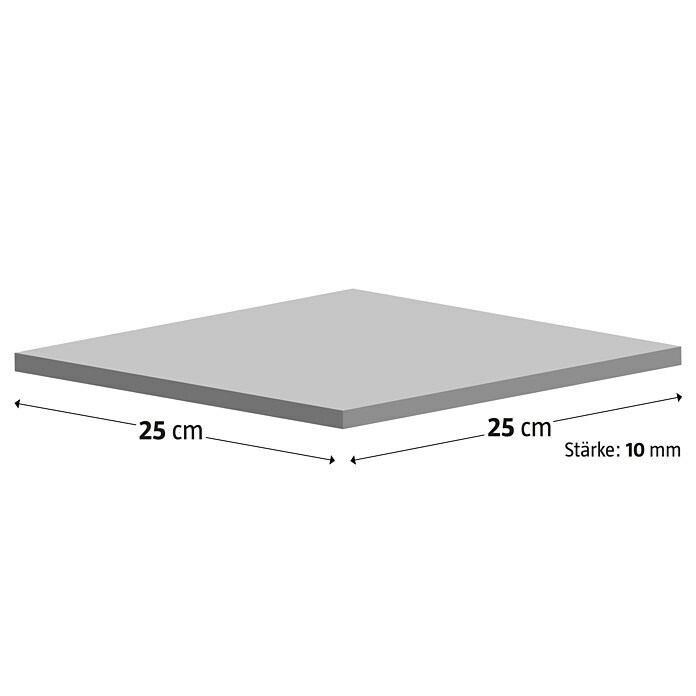

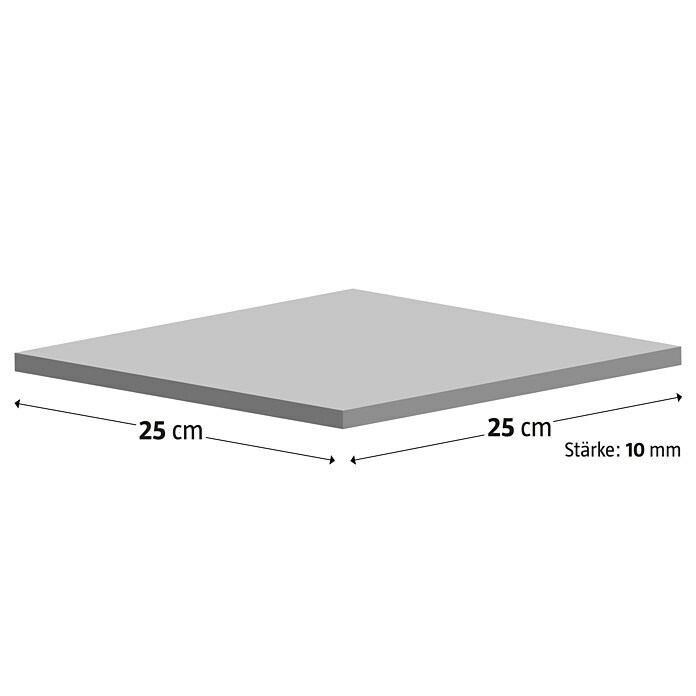

Strength

10mm

Type tile

Floor tile, wall tile

Weather protection

Frost resistant

Width

25cm

length

25cm

scope

Inside, outside

Design tile

Vintage look

Area of application

Living room, kitchen, bathroom

Tile suitable for

Underfloor heating

Sorting

1st choice

Weight (net)

1.275kg

Related products